Non Linear Physics Lab

Description

The fundamental mechanisms responsible of mechanical properties of materials are studied mainly by means of ultrasound and atomic force microscopy techniques. The specific systems under scope are crystalline solids, where dislocations type defects interact with sound waves, fluid gas mixtures, suspensions, granular materials, natural bioceramics and their macromolecules as well as membranes and living cells. In addition, the effect of macromolecules on the bioceramics growth from solution is investigated by means of “in situ” atomic force microscopy. The understanding of a variety of phenomena associated to granular material flows is one of the major goals of the area, 'specially those features that are relevant for practical applications of these materials in local industry. Numerical simulations, statistical mechanics theory and intense experimental activity are developed together for these purposes.

|

|

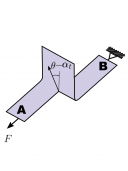

Guided tearing: The ruler testThe physical rules governing the tearing of a packaging or of a piece of paper are not completely elucidated despite being common phenomena in daily life. Here, we investigate how the presence of a straight rigid object, a ruler, guides the fracture of a thin sheet within a wide range of pulling directions. In the case of thin isotropic brittle sheets, a simple geometrical analysis shows that fracture follows the direction of a tearing vector, which differs significantly from the pulling direction. In addition to geometry, bending energy or material anisotropy has to be implemented in the case of thicker or anisotropic sheets, to predict the direction of propagation. A generalization of the Wulff-type construction introduced by Takei et al. [Phys. Rev. Lett. 110, 144301 (2013)] accounts successfully for our experimental results. |